Successful endavours

- Generation of Market Analysis

- Generation of EP system level specification

- Performing of two SRR Milestones to converge on the EP system level specification.

- Setup of a universal LEO Thruster Module optimized for Mass production

- Harmonization of Interfaces

- Design Finalization of LEO Thruster module

- Continuation of environmental tests on LEO Thruster module

- Creation and Delivery of LEO Preliminary Design and PDR data package and preparation of the Milestone

- Start of Production of Flow control unit for LEO Breadboard

Work and results covered by the report

Thales Ulm

The System Design for the both Application lines LEO and GEO (Telecom and Navigation) has been performed. Respective requirement definition has reached maturity to start creation of the hardware deliverables.

A 700W Thruster module has been designed and will be ready for test soon, that evens out the performance difference to thrusters of the same power class on the market. The Module is designed for high volume production and is adequate in particular for mega constellations. It maintains the inherent advantages of the HEMPT-Technology such as flexibility, simplicity and high lifetime. The concept can be transferred to larger scaled thrusters of higher power in the GEO-Application inline within this program.

A LEO-PPU optimized for Cost has been conceptuated. It will allow to use the 700W Thruster Module among others in the different LEO Applications together with the new innovative fluidic control elements.

A Flow control system comprised by a high and a low pressure part has been designed and first models are currently in production. The units are reduced in size, Cost, mass in comparison with traditional Components and provide better control and manufacturability.

TAS-D

TAS in Germany has supported to the EP system level requirements specification and Fluidic Management System level specifications. The preliminary design of the FCU for the HEMPT-NG project was created. Tools (e.g. GSE), processes for manufacturing and test procedures have been completed. Lower level specifications are finished and piece parts production is ongoing.

The project has reached the following impact elements

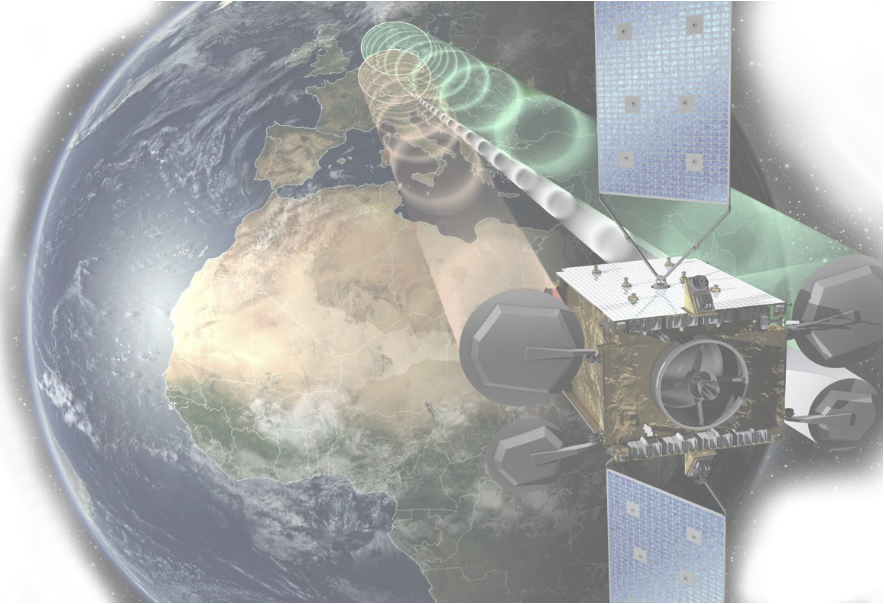

To develop, in the mid-term, the European capacity to compete in the worldwide arena of EP satellites.

We managed to develop a portfolio of products, that can be assembled into different topologies of EP-Solutions. When further developed and maturated these products enable our companies to offer attractive solutions able to compete with other companies.

To substantially increase medium and long term competitiveness of existing EP system technologies with a technology/application-driven approach.

Strong cost reduction efforts where conducted and have proven to be successful. For instance we have reached costs that allow us to offer solutions, that are considered by potential customers for their offers.

To pursue developments which shall be mainly market-oriented, beneficial at system level and with a strategic view to long term needs.

The system was developed in a holistic view involving all the partners to agree on the cost driver elements. The modularity of the individual elements allows to remain flexible within changing market demands. The used concepts are compatible to be upscaled in particular in view of long-term market evolution e.g. such as scientific applications or lunar industry concepts.

Scientific Publications

37th International Electric Propulsion Conference, June 19. – 23.2022

37th International Electric Propulsion Conference, June 19. – 23.2022

Applied Sciences. (open access)

ACTA ASTRONAUTICA

Frontiers in Physics

PROGRESS IN AEROSPACE SCIENCES

Conferences and Workshops

EPIC Workshop 2022, Cologne/Germany, 4.-8. April 2022

EPIC Workshop 2023, Naples, Italy, 9.-12. May 2023

Recent Conferences & workshops

| EPIC Workshop 2022 | Cologne/Germany | 4. – 8. April 2022 | |

| EPIC Workshop 2023 | Naples/Italy | 9.—12. May 2023 |