Methodology for Fluidic Management System

For a single thruster mission which are predominantly in the LEO segment, this can be addressed by a design which combines EPR and FCU, called RADICAL. This configuration is flight proven (TRL 9, Xenon, MEOP 150 bar) and currently used for low-cost LEO applications.

The straightforward design of the RADICAL is compatible with missions using a thruster operating at a single working point. In order to exploit the potential of the HEMP thruster to be operated at different working points in order to perform different tasks e.g. orbit raising and station keeping, we will investigate the possibility to use additional simple parts to extend the RADICAL design in order to be compatible with multiple working points.

This could yield an overall improved cost structure for this type of missions. For ultimate low cost cases these add on components may be omitted for cost reasons. Based on these candidate elements a best topology is decided and confirmed in CDR. Then a specimen is built or reused and missing qualification gaps are closed by unit tests and coupling tests.

For a single thruster mission which are predominantly in the LEO segment, this can be addressed by a design which combines EPR and FCU, called RADICAL. This configuration is flight proven (TRL 9, Xenon, MEOP 150 bar) and currently used for low-cost LEO applications.

The straightforward design of the RADICAL is compatible with missions using a thruster operating at a single working po...

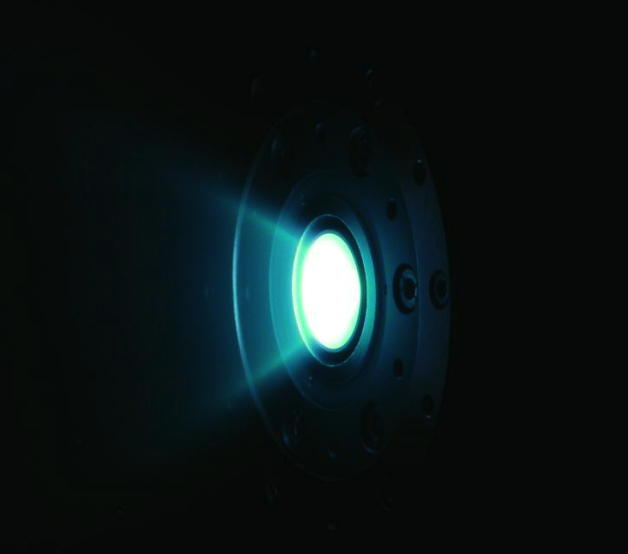

Radical FCU

The starting point within this project is the Radical FCU. The FCU is operated using timed opening of the individual valves. However, this concept relies on a fixed split ratio to neutralizer and anode flow. This creates the drawback of operational losses of propellant and the inability to efficiently operate other than the preselected working point. In consequence, HEMPT would lose two main advantages of its technology.

One resolution among others of these drawbacks might be as follows:

An additional valve in combination with a flow restrictor is used to throttle the flow in one flow line by actuating the valve in a pulse width modulation scheme.

This is the same concept as used in ASTs miniaturized low pressure Flow Control Unit (µFCU). While the µFCU uses low pressure valves, AST proposes to use a high pressure valve for this specific application due to its flight heritage and intrinsic safety.

The corresponding internal flow restrictor is completely replaced by the additional valve and flow splitter without affecting the design heritage of the RADICAL. An additional plenum in combination with the external flow restrictor can act as a filter to damp the ripple generated by the PWM switching of the valve.

The main advantage of this concept is that more than two thruster working points can be covered due to the throttle range provided by PWM valve actuation.